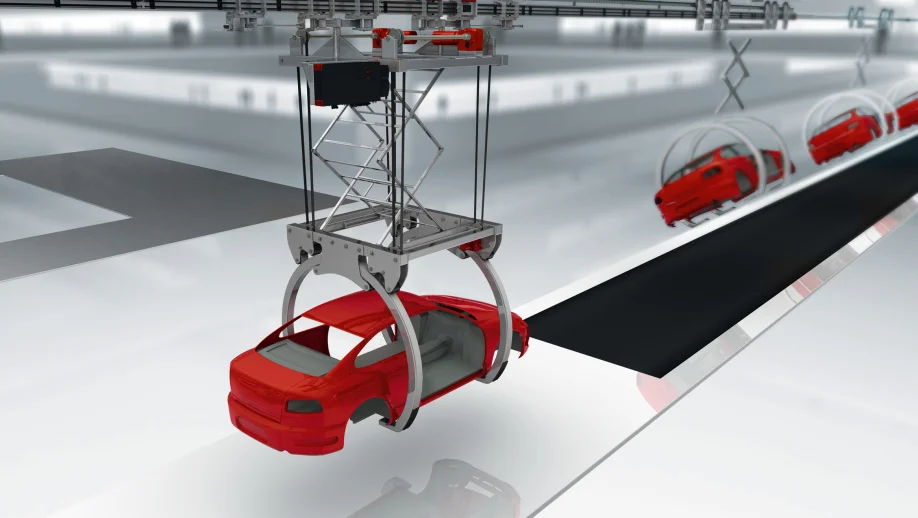

MAXOLUTION® established globally standardized, scalable skillet solutions ranging from simple solutions to high-level safety systems.

Our skillet portfolio

- The MAXOLUTION® solution for skillets with shielded WLAN communication: Skillet advanced

- The MAXOLUTION® solution for skillets with safe communication: Skillet safety

Your benefits

-

Everything from a single source

complete control and drive system ranging from the stationary control level to the control and sensor technology on the vehicles -

Planning security and risk minimization

thanks to a certified project team, simulation and emulation with MOVIVISION®, startup, production facilitation and project acceptance -

Perfectly tailored to your production requirements

the modular systems are integrated into your system via flexible MOVIVISION® software solutions -

Data transparency and high system availability

with intelligent Drive Radar® software solutions for condition monitoring and predictive maintenance Keeping ahead of errors!