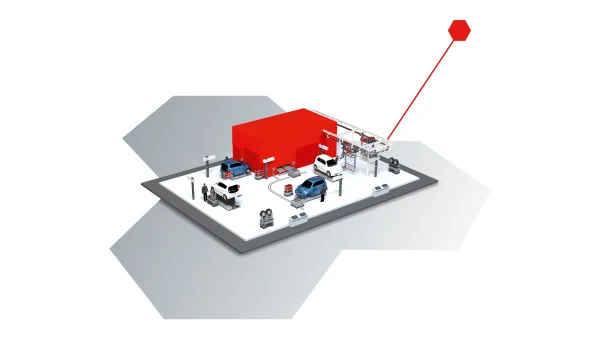

At HANNOVER MESSE 2019, we aim to prove that, for SEW‑EURODRIVE, Industry 4.0 is no longer just a vision of the future. That future has long since arrived – especially in the automotive industry. At Stand F12 in Hall 15 of this world-leading industrial trade fair, we’re giving live demonstrations of our MAXOLUTION® automation solutions for the automotive industry using the final assembly of an automobile as an example.

Live: e.GO assembly in the automobile factory of the future

Driverless technology is evolving rapidly, allowing drivers to get from A to B both comfortably and safely. Even in automobile production, new technologies are becoming all the more popular when it comes to designing the production lines of the future more intelligently, flexibly and efficiently.

Our tried-and-tested MAXOLUTION® automotive solutions support you as you work towards creating your own smart factory and enable you to increasingly network physical and digital processes – throughout the entire value creation system. We’re showing off our many years of experience live at HANNOVER MESSE 2019. You can discover our intelligent process modules, mobile assistance systems, and innovative system solutions by exploring an e.GO assembly line in the futuristic automobile factory we are exhibiting as an example at our stand.

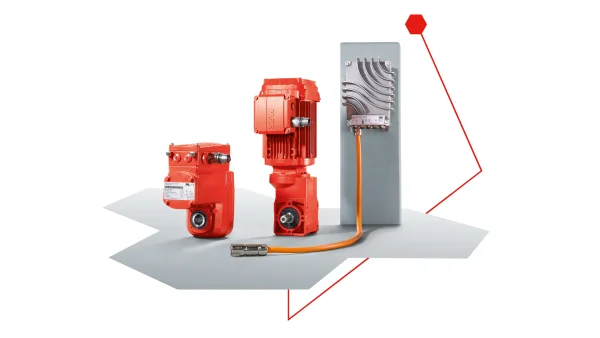

Flexible – modular automation system

Flexibility is an important driver, particularly in automobile production. Our MOVI‑C® automation system offers you precisely the freedom you need to select the ideal components for your system – from drive technology that can be digitally integrated and inverter and control technology right through to engineering software and power & energy solutions. Of course, everything is available for both centralized and decentralized installation concepts – and all from a single source.

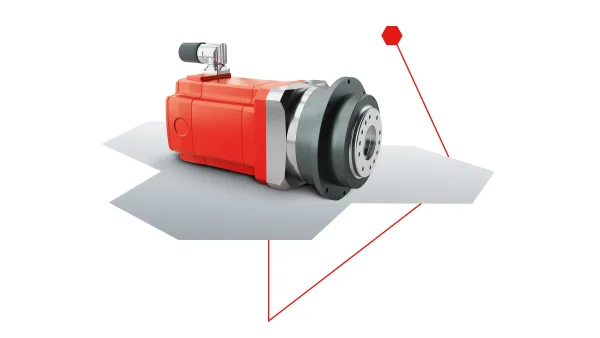

Dynamic – precise movement despite heavy loads

To avoid traffic jams on the highway, you need accurate traffic information. To avoid bottlenecks in production, you need accurate movements. Our new CM3C servomotors with a digital interface move even heavy loads dynamically and with high precision. This is achieved in combination with the new planetary gear units of the PxG series. Whether for dynamics, high speeds or limited space – the 6 available sizes cover a torque range from 20 to 6500 Nm.

Reliable – smart factory services

To remain a reliable partner for our customers in the automotive industry, we work hand in hand with them, offering the best possible services for the automotive industry at every stage of the system life cycle with our MAXOLUTION® portfolio – from consulting, project planning, processing, simulations and emulations, virtual and augmented reality, all the way to installing and commissioning systems and custom maintenance services.

Innovative – knowing what will happen tomorrow

What if you could use real-time data to prevent the potential damage and wear-related defects of the future? We’re redefining maintenance under the umbrella of DriveRadar®. Find out more about our scalable monitoring and preventive maintenance management at HANNOVER MESSE 2019.